Copper

Copper FRHC Rod Lines

Continuus-Properzi solutions for producing Fire Refined High Conductivity (FRHC) copper depends on the kind and qualities of scrap available to each Customer.

Properzi has worked very hard during the last 50+ years to be able to supply FRHC copper rod plants that match the best combination of OEE, CapEx and OpEx.

The term “copper scrap” is a general indication that encompasses all types of scrap from bright and clean copper scrapped in the drawing shop (which is very near to cathode purity) to old scrap, coming from demolition, which is very polluted with a minimum copper content of around 93%.

MAIN ADVANTAGES

| Highest worldwide percentage of premium quality | Widest range of commercial Cu Rod diameters | Best geometrical quality |

| Maximum flexibility in processing Cu cathodes, even of low quality | Perfect coil shape in both concentric and orbital types | Rod quality repeatable and constant |

| Highest rod quality for ETP, exceeding the standards | Increased mechanical properties |

CCR COPPER typical lines configuration

Close –

View +

Close –

View +

*The CCR Line provides a typical line configuration. The position of the main equipment can vary according to specific needs:

| 00. FUME TREATMENTS |

| 01. REFINING FURNACE (SET) |

| 02. SHAFT FURNACE AND HOLDING FURNACE |

| 03. CASTING MACHINE |

| 04. AUTOMATIC BAR SHEAR |

| 05. BAR PREPARATION UNIT |

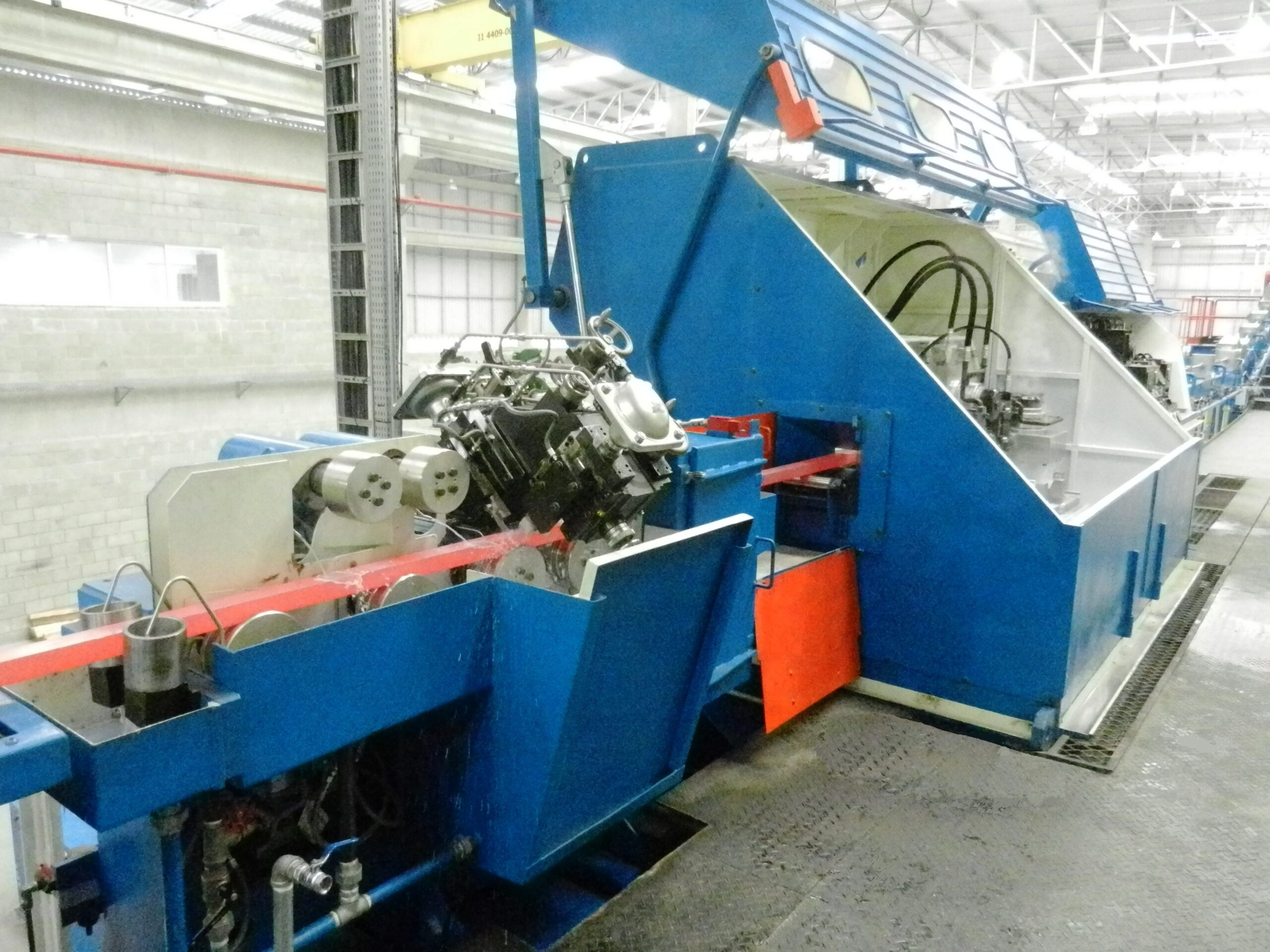

| 06. ROLLING MILL |

| 07. PICKLING UNIT |

| 08. COOLING UNIT |

| 09. WAXING UNIT |

| 10. COILER |

| 11. CONTROL ROOM & ELECTRICAL CONTROL CABINETS |