Ingot lines

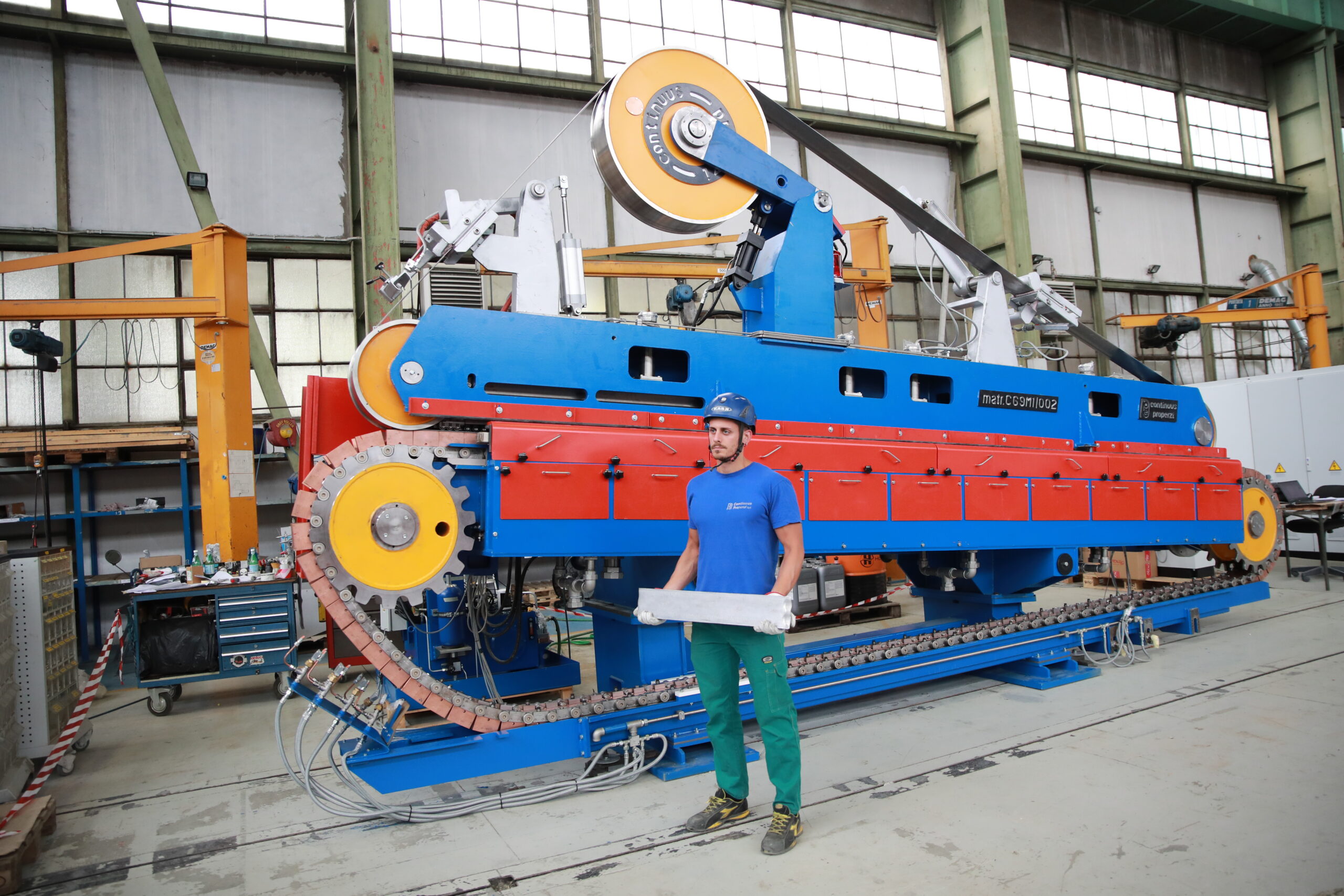

TRACK & BELT

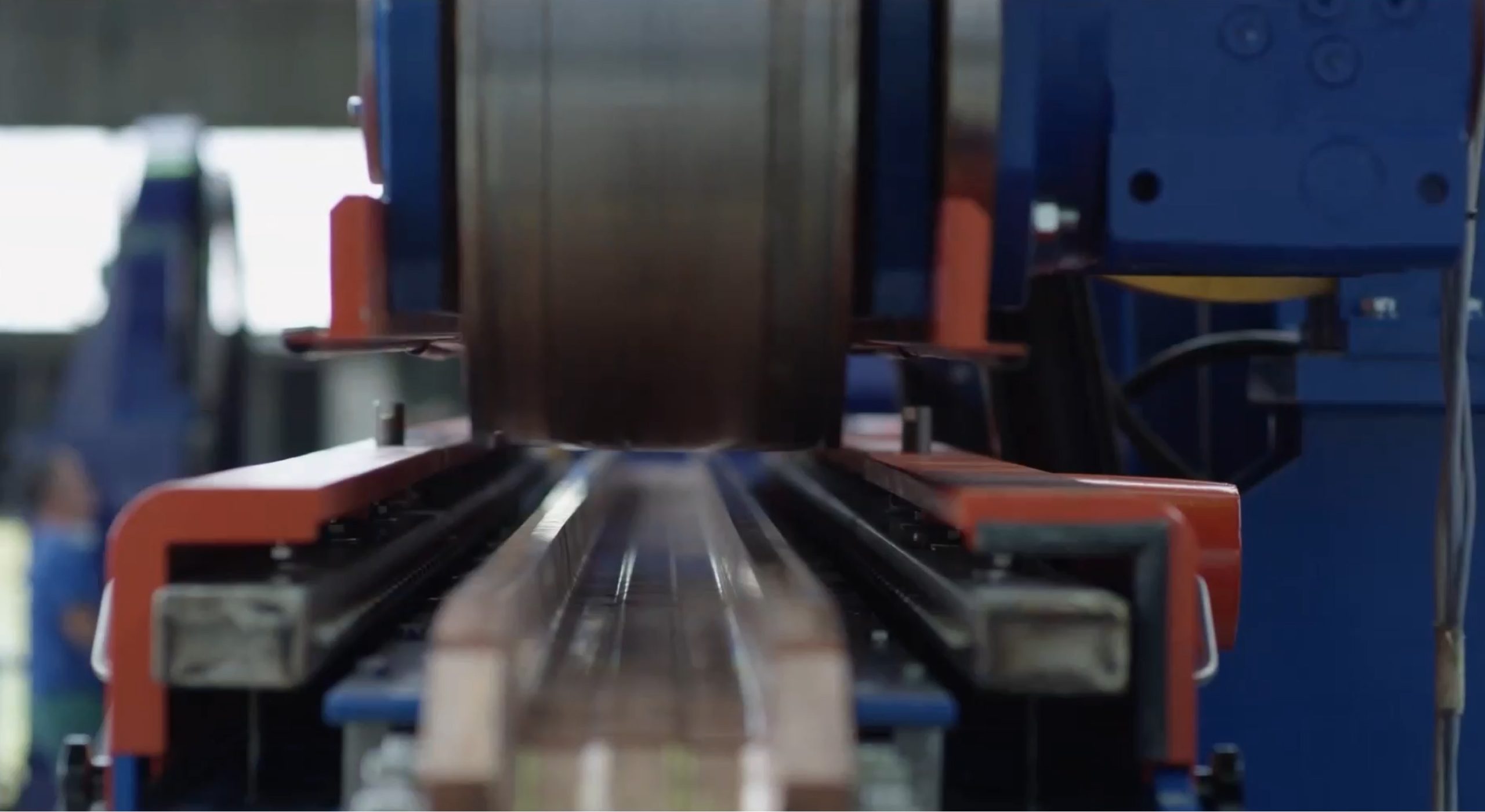

The recently patented Properzi Track & Belt Ingot Casting Machine Model 1 and Model 2 transform the molten metal into a continuous cast straight bar of trapezoidal shape with total repeatability. Discover our Continuus green ingots!

The cast bar is cut into ingots of precise length by a rotary shear. The ingots are then cooled in line to a temperature of 70-80°C in order to allow the palletization and strapping operations with plastic or steel straps.

The Track & Belt process is gaining wide acceptance in many countries and can work either in continuous operation reaching an Overall Equipment Efficiency (OEE) exceeding 90% or on a batch basis.

For many years ingots have been produced with the traditional mould chain and such ingots are referred to as “Open Top Ingots” in the market. Although many improvements have been made over the years, several problems related to the general design concept remain unresolved.

TRACK & BELT typical lines configuration

Close –

View +

Different plant configurations can provide ingot production rates ranging from 10 tph or higher for secondary alloys up to 28 tph for pure aluminium. Lines to produce ingots of special size and weight tailored to customer needs are available upon request. Properzi is also able to supply such plants on an Engineering, Procurement and Construction (EPC) basis so that the buyer is only minimally involved with the installation of the plant.

| 01. CASTING MACHINE |

| 02. CAST BAR COOLER |

| 03. OPTICAL PYROMETER |

| 04. STAMPING PINCH ROLL |

| 05. ROTATORY SHEAR |

| 06. TILTABLE CONVEYOR |

| 07. INGOT CONVEYOR |

| 08. INGOT KICK-OUT CONVEYOR |

| 09. INGOT COOLING TUNNEL |

| 10. INGOT STACKING ROBOT |

MAIN ADVANTAGES

| 100% repeatable shape, dimensions and weight | The cast bar is solidified with zero cracks and no dangerous voids | Zero de-molding problems |

| Consistent dimensions and shape of ingot bundles with high stability | Skimming is not required | Minimum number of straps needed |

| 25% less space required for storage | Traceability data mechanically imprinted | Easy to handle |

Properzi equipment installed since our founding in 1947.

*It may not coincide with the number of Properzi plants currently in operation.