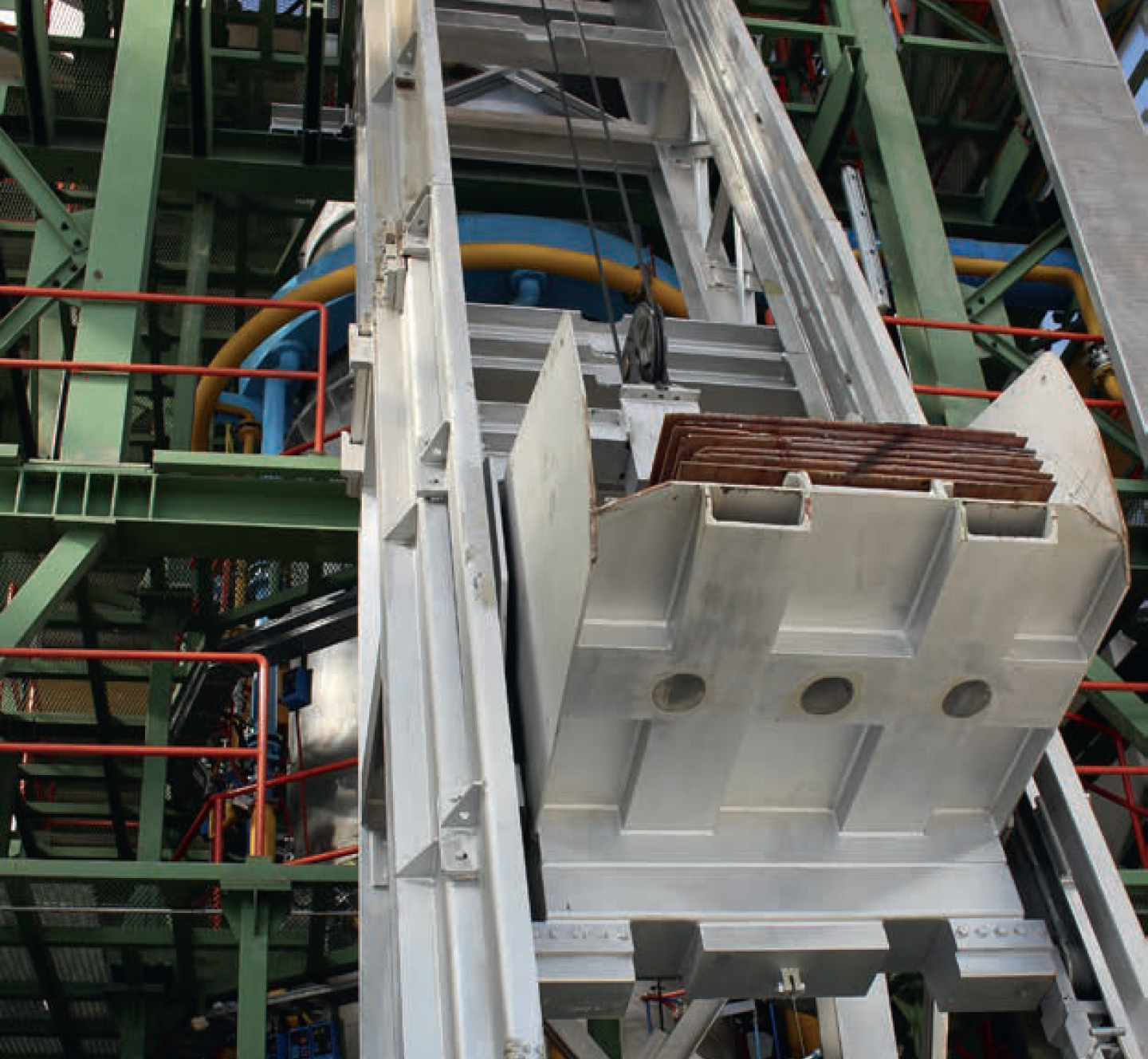

COPPER FURNACES

Shaft+Holding

Properzi has a 40 years long experience in designing such furnaces and was the first developer of the pre-mix burner system that today is adopted by all producers.

The melting rate and the combustion quality are strictly controlled by Properzi’s state-of-the-art burner combustion system, where the combustion air-to-fuel ratio of each burner guarantees consistent melting at the desired value.

The thermal consumption of a Properzi Shaft Furnace is the lowest in this type of application and the quality of the liquid copper, collected in the Holding Furnace, is suitable for the most severe applications and standards.

MAIN ADVANTAGES

| The optimal combustion parameters facilitate optimization of flame quality, negligible dissolved hydrogen, improved refractory service life and fuel savings. | Maximum flexibility in terms of design, scope of supply and configuration. |

OPTIONS IN SIZE

SMALL OUTPUT RATE

Production rate: from 5 tph to 10 tph

Expected yearly output: from 25,000 to 58,000 tons

MEDIUM OUTPUT RATE

Production rate: from 12.5 tph to 20 tph

Expected yearly output: from 61,000 to 115,000 tons

LARGE OUTPUT RATE

Production rate: from 25 tph to 40 tph

Expected yearly output: from 125,000 to 250,000 tons